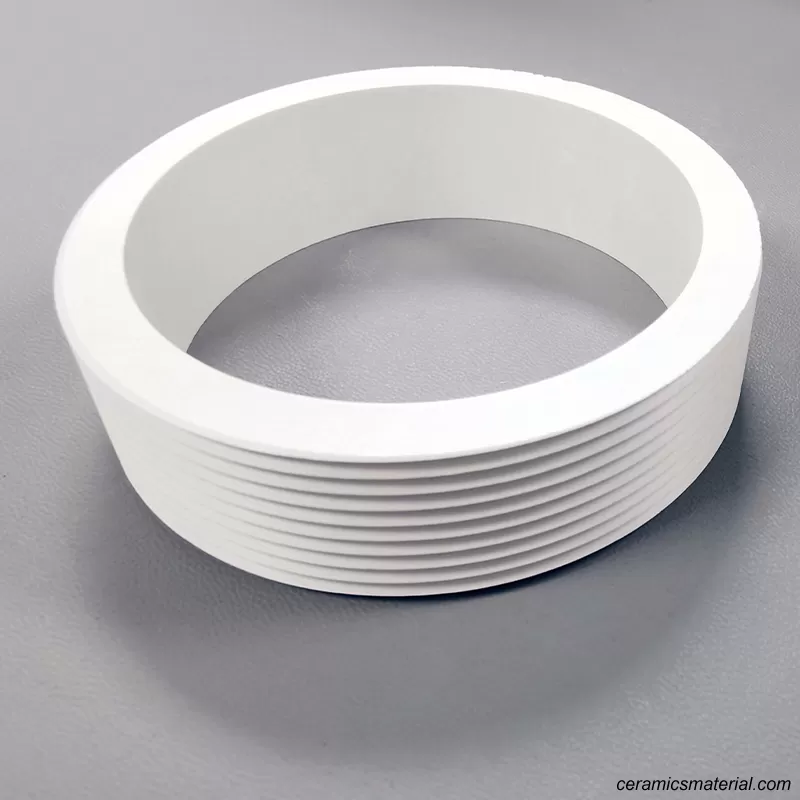

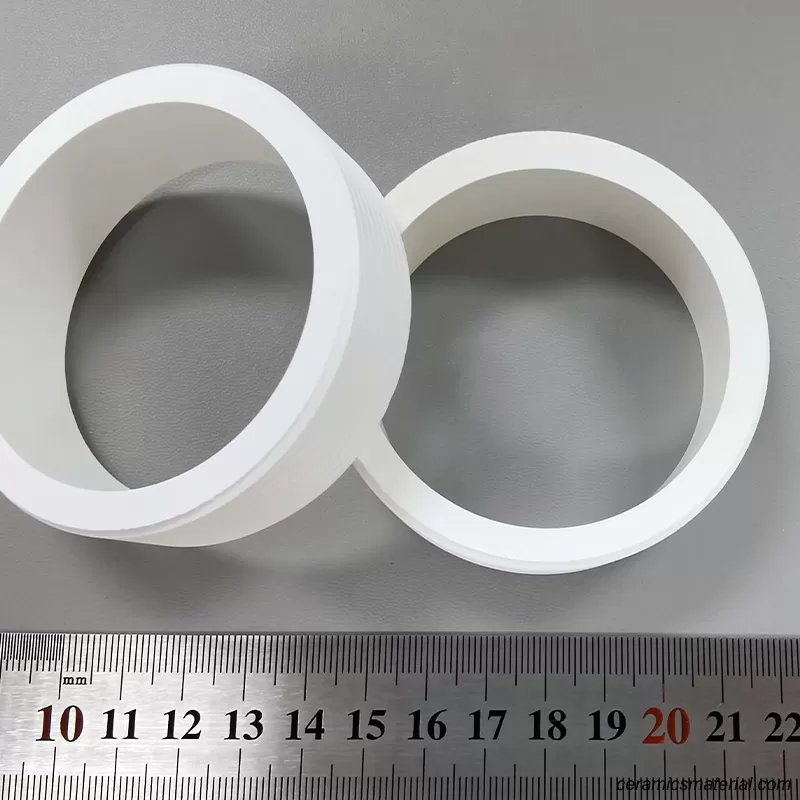

Boron nitride ceramic threaded fastening ring

- Category:Nitride Ceramics

- FOB Price:Get Latest Price Now

- Quality Guarantee:12 Months unless specified otherwise

- Place of Origin:China

- Custom description:Customizable production based on drawings

China Boron nitride ceramic threaded fastening ring Introduction:

Specifications

- Brand Name

- OEM

- HS Code

- 6914100000

- Unit

- PCE(Pieces)

- Customed Made

- Yes

- MOQ

- 10

- Delivery Period

- 5 days

Description

Boron nitride threaded fastening ring introduction:

Boron nitride ceramic, also known as hexagonal boron nitride ceramic, boron nitride ceramic fastening ring has good heat resistance, thermal stability, thermal conductivity and high temperature dielectric strength, making it an ideal application for heat dissipation and high temperature insulation environments. Boron nitride ceramic fastening rings have good chemical stability, can resist the erosion of most molten metals, and have excellent self-lubricating properties. Boron nitride ceramics can withstand high temperatures in high vacuum environments and have excellent resistance to corrosion and corrosion. Therefore, BN ceramic products are ideal for many industries.

Application scope of boron nitride ceramic fastening ring:

1. Crucible used for melting semiconductors;

2. High-temperature vessels for metallurgy;

3. Semiconductor heat dissipation and insulation parts;

4. High temperature bearings;

5. Thermowell;

6. Glass forming mold.

Boron nitride ceramic properties

1. High heat resistance: sublimates at 3000°C; at 1800°C, its strength is twice that at room temperature. It will not break when cooled from 1500°C to room temperature dozens of times; it will not soften in an inert gas at 2800°C.

2. High conductivity: hot pressed products are 33W/MK, the same as pure iron. Above 530℃, it has the maximum thermal conductivity above 530℃.

3. Low thermal expansion coefficient: Its thermal expansion coefficient is 2×10-6, second only to quartz glass and the lowest among ceramics. High thermal shock resistance due to high thermal conductivity.

4. Excellent electrical properties: excellent high temperature insulation; up to 1014Ω-cm at 25℃ and 103Ω-cm at 2000℃. So it's the best high temperature. Insulating materials in ceramics. When the breakdown voltage is 3KV/MV, the low dielectric loss is 108HZ, it can reach 2.5×10-4, the dielectric constant is 4, and it can penetrate microwave and infrared rays.

5. Extremely strong corrosion resistance: will not react with ordinary metals (iron, copper, aluminum, lead, etc.), rare earth metals, precious metals, semiconductor materials (germanium, silicon, potassium arsenide), glass, molten salt (crystal) , fluoride and slag), inorganic acids and bases.

6. Low friction coefficient: U is 0.16 and will not increase at high temperatures. It has higher high temperature resistance than molybdenum disulfide and graphite. The oxidizing atmosphere is 900°C; it can be used at 2000°C under vacuum.

7. High purity and high boron content: the impurity content is less than 10PPM and the boron content exceeds 43.6%.

8. Machinability: Its hardness is Mohs 2, so it can be processed into high-precision parts and components through conventional machining.

Service

Welcome to consult China Boron nitride ceramic threaded fastening ring suppliers. We have more than 10 years of foreign trade supply experience and provide you with high-quality precision ceramics customized supply services and wholesale preferential prices customized by manufacturers. You can get a free quote online or leave a message below and we will reply to you within 24 hours.

Share this China Boron nitride ceramic threaded fastening ring

Similar Precision Ceramics

One step to find us,we will respond within 24 hours