Introduction and application of alumina insulating ceramics

1. Overview of alumina insulating ceramics

Alumina insulating ceramics, with α-Al2O3 as the main crystal phase, have excellent mechanical strength, thermal conductivity, electrical strength and high insulation resistance. In addition, its dielectric loss is low, and its electrical properties are relatively stable with changes in temperature and frequency. This ceramic material is easy to manufacture, has a uniform and flat surface, and is low in cost, so it is widely used in the field of electrical insulation. Alumina ceramics are the most widely used type of electronic ceramics, and the proportion of electrical insulating ceramics in electronic ceramics cannot be underestimated.

2. Formula composition of alumina insulating ceramics

95 porcelain is a type of alumina ceramic, usually with CaO, MgO, SiO2, and transition metal and rare earth metal oxides as additives. These additives enable 95 porcelain to be sintered at a lower temperature, and its microstructure usually contains 10% of glass phase and subcrystalline phase. In the CaO-Al2O3-SiO2 phase diagram, the lowest eutectic temperature is 1495℃.

The advantages of MgO-Al2O3-SiO2 ceramics are their good acid resistance and small grain structure, but the sintering temperature is slightly higher than that of CaO-Al2O3-SiO2. The introduction of rare earth oxides such as Y2O3 and La2O3 can further reduce the sintering temperature.

CaO-MgO-Al2O3-SiO2 ceramics combine the advantages of low sintering temperature and fine grains, have a dense organizational structure and strong resistance to acid and alkali corrosion, and are an ideal white porcelain system.

95 porcelain can also add BaO. Ceramics produced in the BaO-Al2O3-SiO2 system can produce excellent performance mullite porcelain and corundum-mullite porcelain according to different compositions. Ceramics in this system have a smooth surface, good acid and alkali corrosion resistance and high volume resistivity. Adding transition metal oxides such as Cr2O3, MnO2, and TiO2 can produce colored 95 porcelain with low sintering temperature, high mechanical strength, good wear resistance and metal sealing properties.

Kaolin, bentonite, barium carbonate and other additives are added to 75 porcelain, which is divided into porcelain with SiO2 as the main additive and porcelain with a small amount of alkaline earth metal oxides such as CaO, MgO, BaO, etc. The latter is mainly corundum and has less mullite phase.

3. Manufacturing process of alumina insulating ceramics

Alumina ceramics contain less clay and the main component is alumina. Its production process includes grinding in a ball mill, while avoiding iron and other impurities. Grinding media and linings should use alumina or corundum porcelain, or rubber. The fineness of the raw materials has a significant effect on the sintering temperature and performance of the product. The higher the fineness, the lower the sintering temperature and the higher the flexural strength.

Due to the poor plasticity of 95 porcelain and 75 porcelain blanks, organic plasticizers need to be added. The molding method is determined by the shape of the product and the nature of the ingredients, including dry pressing, grouting, hot die casting and isostatic pressing.

4. Application of Alumina Insulating Ceramics

Alumina ceramics are used as electrical insulating materials, including corundum ceramics, high-alumina ceramics, 75 ceramics and colored alumina ceramics. 95 ceramics, 96 ceramics and 99 ceramics are often used in electric vacuum technology as dense ceramic packaging tubes and shells for ceramic-metal sealing.

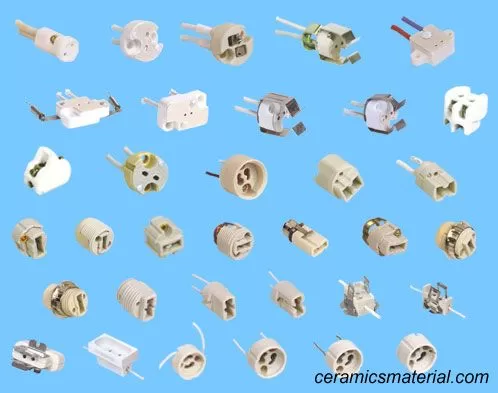

In the application of dielectric ceramics, alumina ceramics are mainly used for substrates, shells, fixings, sealing or insulating parts in electronic components and circuits, such as insulators, resistor substrates, integrated circuit substrates, packaging tubes and shells, etc.

Share the Introduction and application of alumina insulating ceramics

Recent News

- Study on high-temperature hydrophobic modification and f...2024-08-19

- Research progress on thermal protection coatings on niob...2024-08-19

- Application and introduction of nitride insulating ceram...2024-08-08

- Introduction to the manufacturing process and applicatio...2024-03-05

- Introduction and application of 95 alumina precision cer...2024-02-28

- Introduction to the characteristics, processes, and appl...2024-02-28

- Introduction and application of alumina precision cerami...2024-01-22

- Diversified applications of precision ceramic materials:...2023-12-19

- Comparing precision ceramic cleavers, diamond knives, an...2023-12-16

- Advantages of precision ceramic dispensing valves compar...2023-12-07