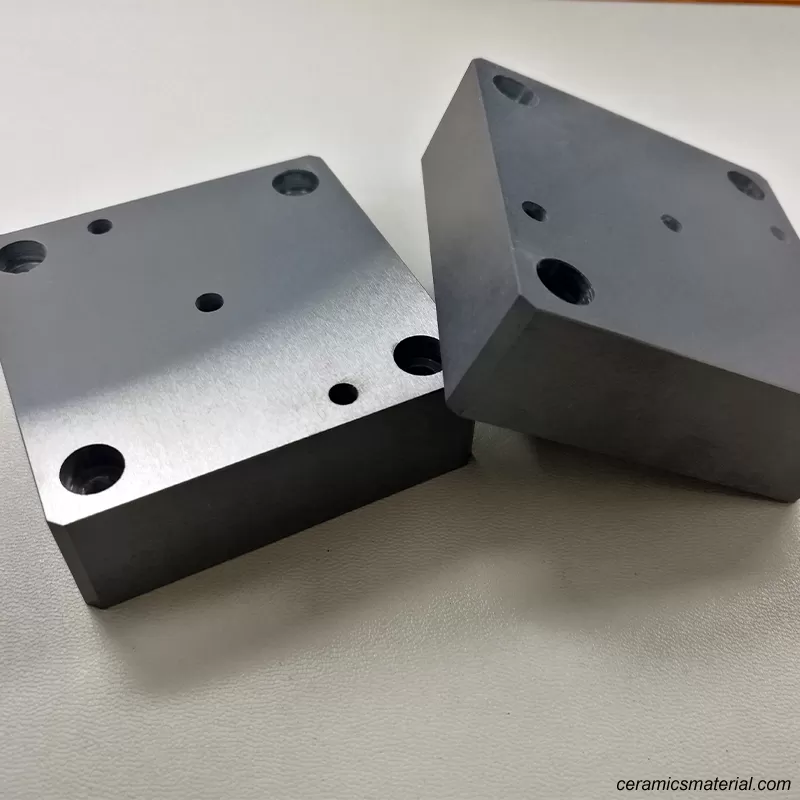

Square silicon nitride ceramic structural parts (version 1)

- Category:Nitride Ceramics

- FOB Price:Get Latest Price Now

- Quality Guarantee:12 Months unless specified otherwise

- Place of Origin:China

- Custom description:Customizable production based on drawings

China Square silicon nitride ceramic structural parts (version 1) Introduction:

Specifications

- Brand Name

- OEM

- HS Code

- 6914100000

- Unit

- PCE(Pieces)

- Customed Made

- Yes

- MOQ

- 10

- Delivery Period

- 7 days

Description

Silicon nitride ceramic description

Silicon nitride ceramics are mainly composed of Si3N4 and have excellent thermal shock resistance and high temperature strength. These properties make it an ideal material for automotive engines and gas turbines. It can be used in various applications such as turbocharger rotors, diesel engine hot swapping, hot swapping, etc.

Silicon nitride ceramics are one of the most versatile combinations of mechanical, thermal and electrical properties of any technical ceramic material. It is a high-performance technical ceramic that is very hard and has excellent thermal shock and impact resistance. It exceeds the high temperature performance of most metals and has excellent creep and oxidation resistance. Additionally, its thermal conductivity and wear resistance are among the most demanding in the most demanding industrial applications. Silicon nitride is an excellent choice when high temperatures and high load capabilities are required. .

Silicon nitride ceramic material properties

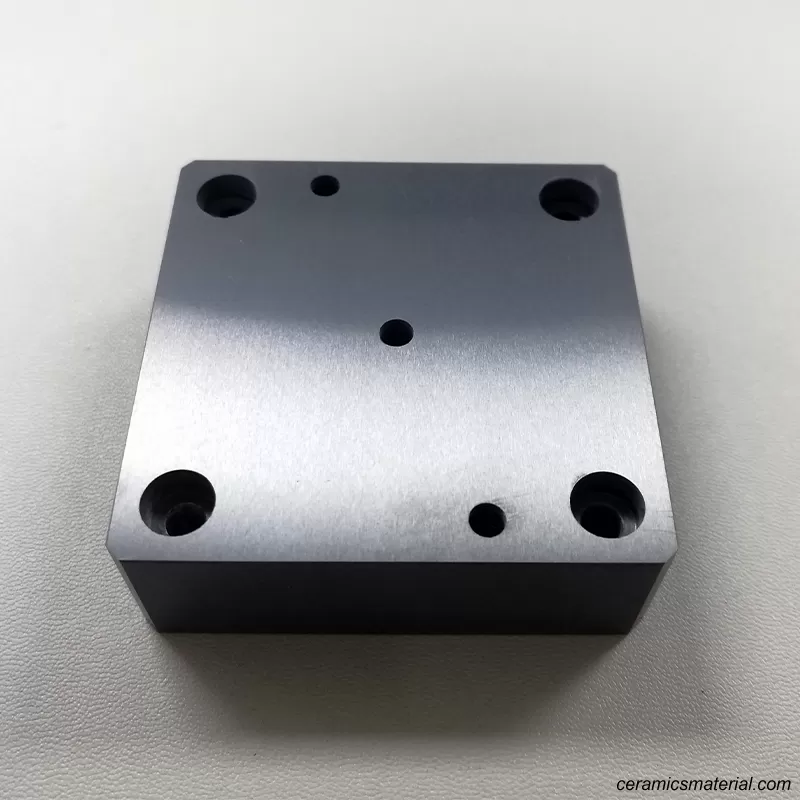

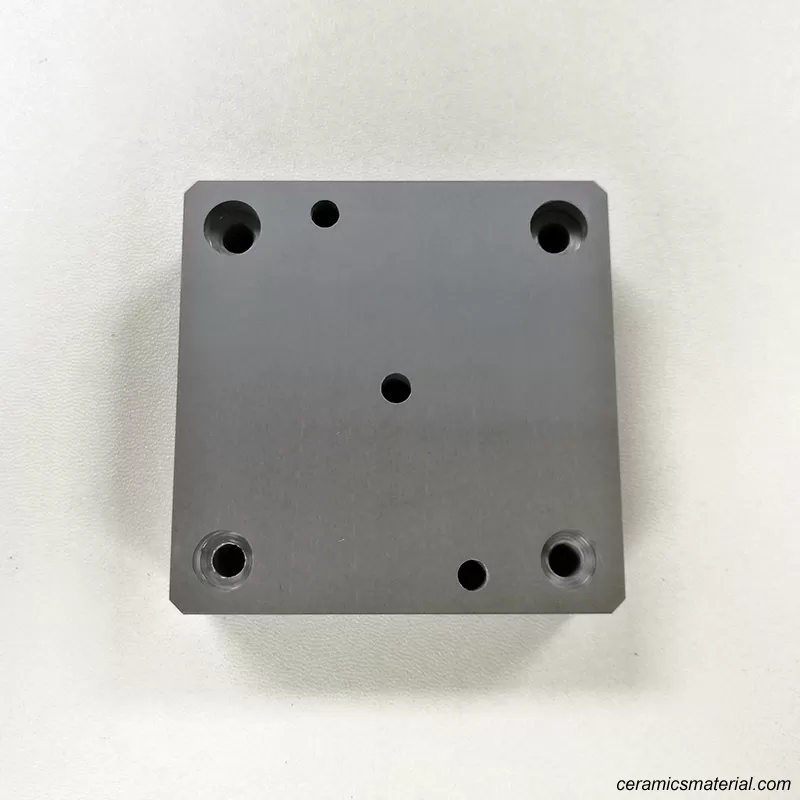

1.Shape and size can be customized as needed

2. Vickers hardness (HV50): 14 (Gpa)

3. Extremely low density (3.21 g/cm³)

4. Excellent thermal shock resistance: high thermal stress parameter (569K)

5. Maximum working temperature of oxidizing atmosphere: 1200°C

6. Extremely low density (3.21 g/cm³)

7. Extremely high fracture toughness (7 MPam1/2)

8. Good bending strength (850 MPa)

9. Maximum operating temperature in neutral atmosphere: 1600°C)

Service

Welcome to consult China Square silicon nitride ceramic structural parts (version 1) suppliers. We have more than 10 years of foreign trade supply experience and provide you with high-quality precision ceramics customized supply services and wholesale preferential prices customized by manufacturers. You can get a free quote online or leave a message below and we will reply to you within 24 hours.

Share this China Square silicon nitride ceramic structural parts (version 1)

Similar Precision Ceramics

One step to find us,we will respond within 24 hours